A DOT vehicle inspection is a mandatory process to ensure commercial vehicles meet federal safety standards. This guide will help you understand the inspection process, types of inspections, and how to prepare. By knowing what to expect, you can ensure compliance and keep your vehicle roadworthy.

Key Takeaways

- DOT Vehicle Inspections are mandatory for commercial motor vehicles to ensure safety and compliance with federal regulations.

- Inspections are categorized into six levels, each with specific requirements, focusing on aspects like driver compliance, vehicle condition, and cargo safety.

- Proper vehicle maintenance and accurate documentation are essential for passing inspections, preventing fines, and maintaining a positive safety rating.

What is a DOT Vehicle Inspection?

A DOT Vehicle Inspection is a critical process aimed at ensuring that commercial motor vehicle (CMV) are in optimal working condition, enhancing safety on our roads. These inspections are mandatory under federal motor carrier safety regulations (overseen by the Department of Transportation (DOT)) and play a crucial role in preventing accidents and promoting public safety through commercial motor vehicle certification. Additionally, commercial drivers must ensure compliance with these inspections to maintain safety standards.

DOT inspections are required for vehicles and commercial drivers engaged in interstate commerce, and the gross vehicle weight rating (GVWR) of a vehicle determines whether it is subject to these inspections. Achieving DOT certification means that transportation organizations adhere to strict safety regulations, which helps minimize the risks of non-compliance and potential accidents.

Types of Inspections

DOT Vehicle Inspections are categorized into six distinct levels, each with its own focus and requirements. Level 1 inspections, known as the North American Standard Inspection, are the most comprehensive and include:

- A full examination of the vehicle

- A full examination of the driver’s documentation

- Inspection of brake systems

- Review of the driver’s logbook

Level 2 inspections, while still thorough, do not require inspectors to go underneath the vehicle but include all documentation checks from Level 1.

Level 3 inspections focus solely on the driver’s credentials and compliance, such as the commercial driver’s license (CDL) and the medical examiner’s certificate. Inspectors verify that the driver holds a valid CDL and a current medical examiner’s certificate, which is required to demonstrate that the driver meets the health standards necessary for operating commercial vehicles.

Level 4 inspections are specialized and often one-time evaluations targeting specific vehicle issues or claims.

Level 5 inspections mirror the Level 1 inspection but are conducted without the driver present. Enhanced NAS inspections for radioactive shipments, classified as Level 6, require rigorous checks of the vehicle, driver, and cargo to ensure the highest safety standards. These inspections are specifically required for vehicles that carry hazardous materials.

Who Performs DOT Inspections?

DOT inspections are typically conducted by state troopers and officials from the Department of Transportation Federal Motor Carrier Safety Administration (FMCSA). These authorities are trained to ensure compliance with federal laws, making sure that both the vehicle and the driver meet all necessary safety standards.

DOT physicals ascertain the driver’s fitness and vital signs, further ensuring vehicle safety through a dot physical examination that is dot certified and requires driver certification, including a dot medical exam, a dot medical card, and a drug test to perform dot physicals and a dot physical exam and a dot card, adhering to dot physical requirements and ensuring that drivers are physically qualified. DOT physicals must be performed by a licensed medical examiner who is listed on the FMCSA National Registry, which includes qualified healthcare providers such as doctors of medicine, osteopathy, chiropractors, and advanced practice nurses.

These services are widely available and can be accessed at various locations to ensure driver compliance.

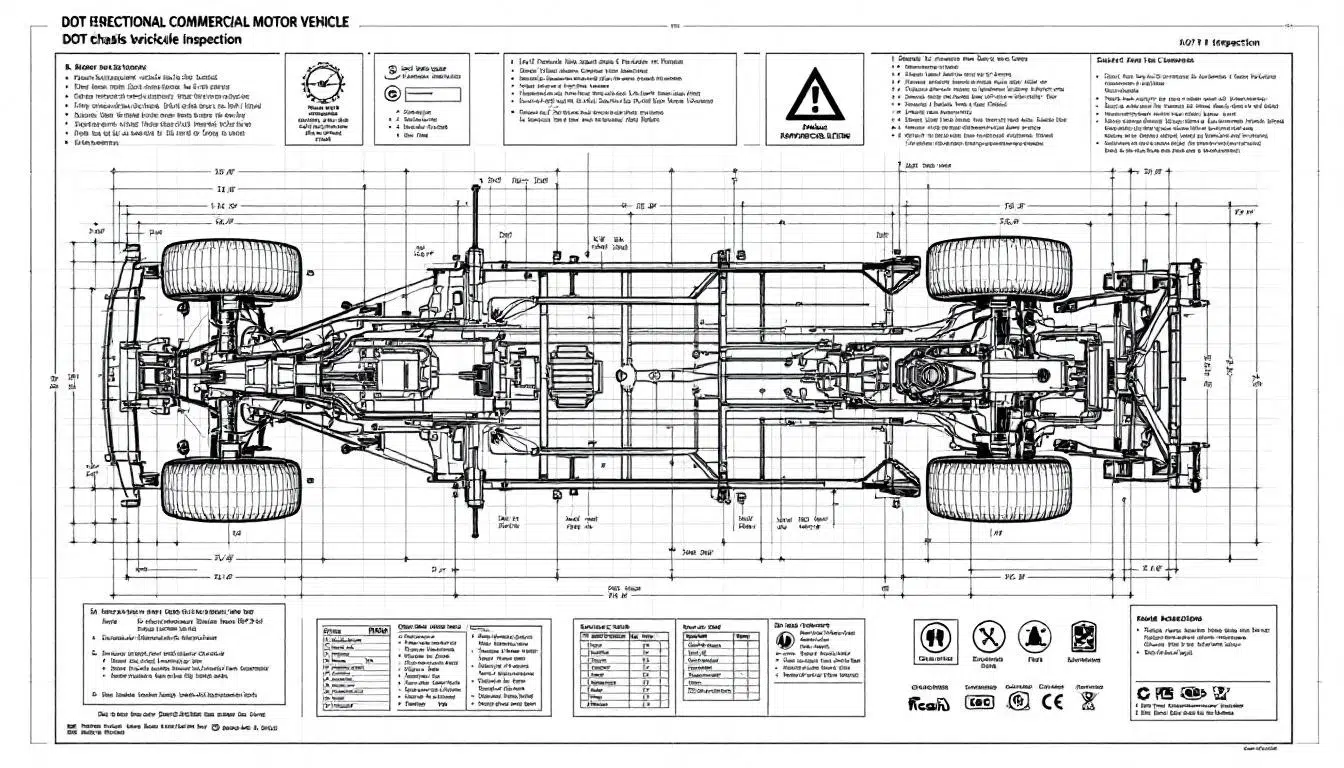

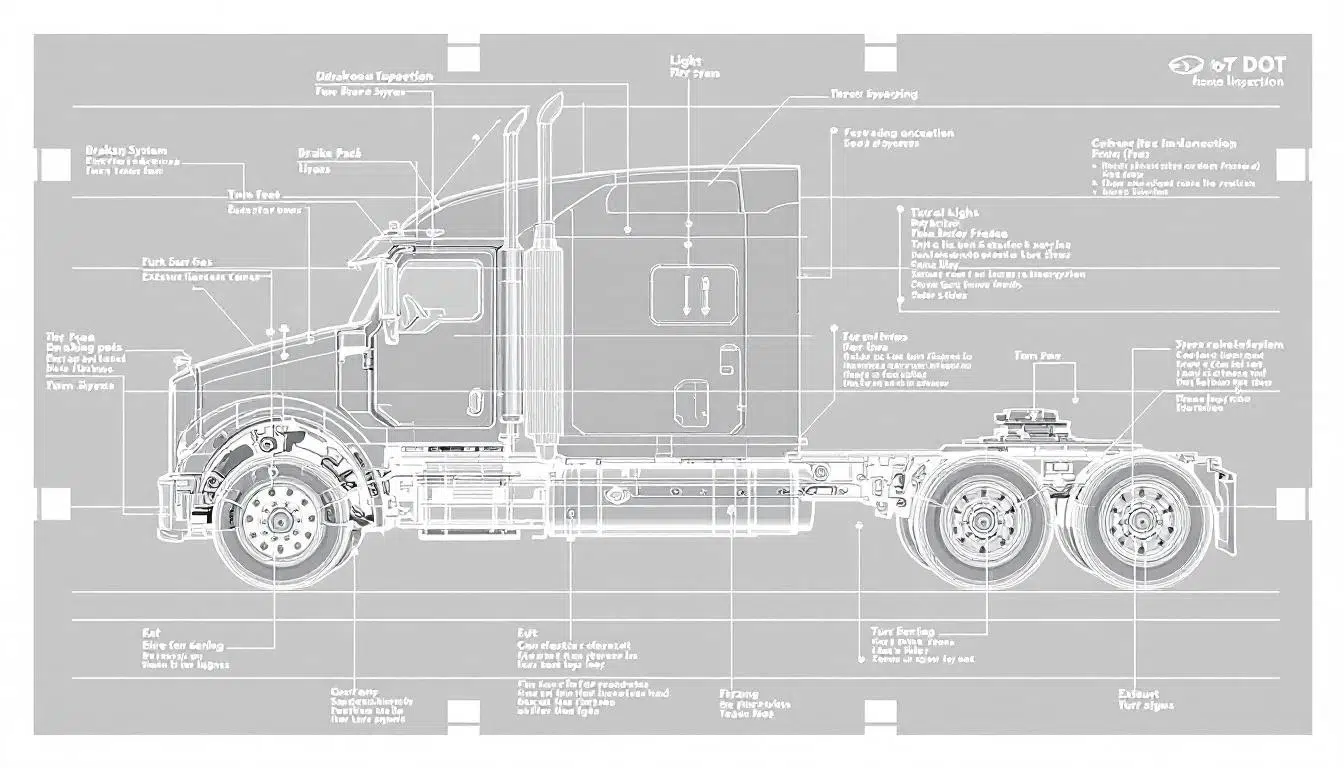

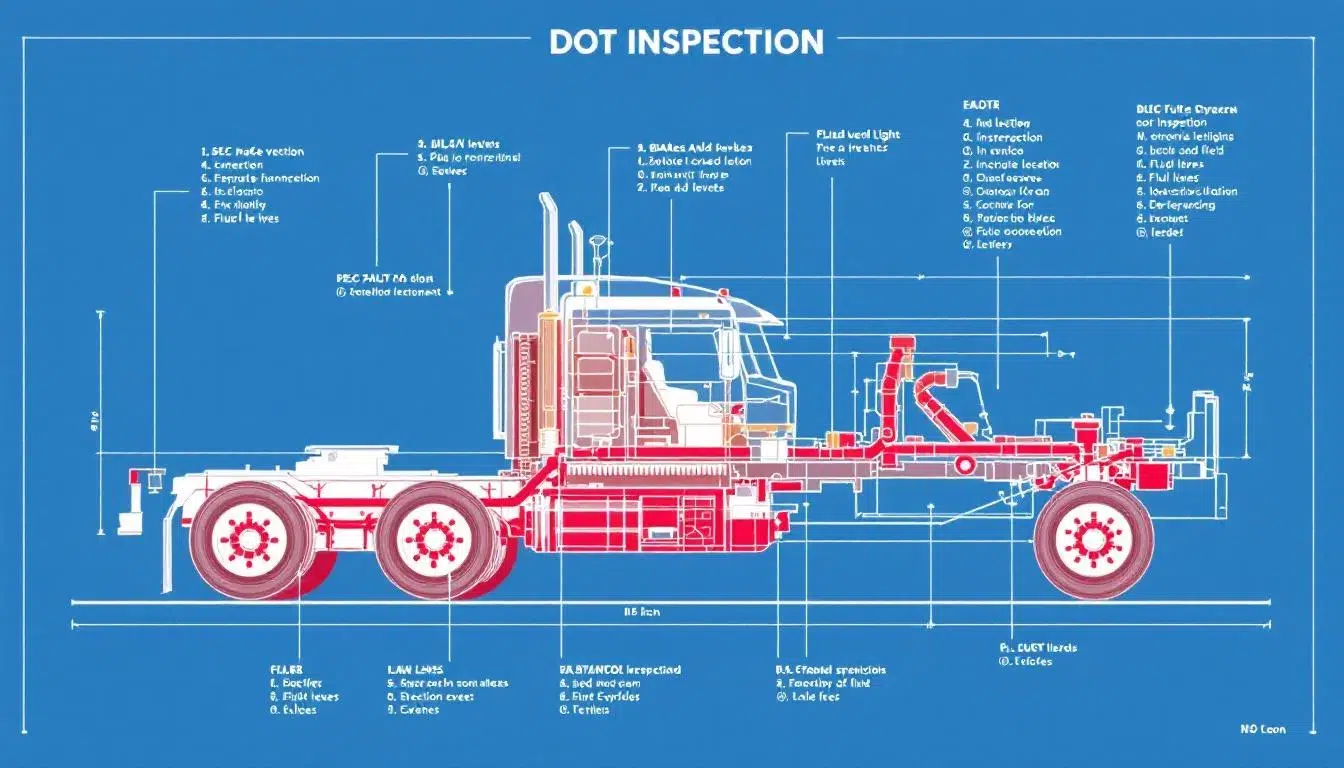

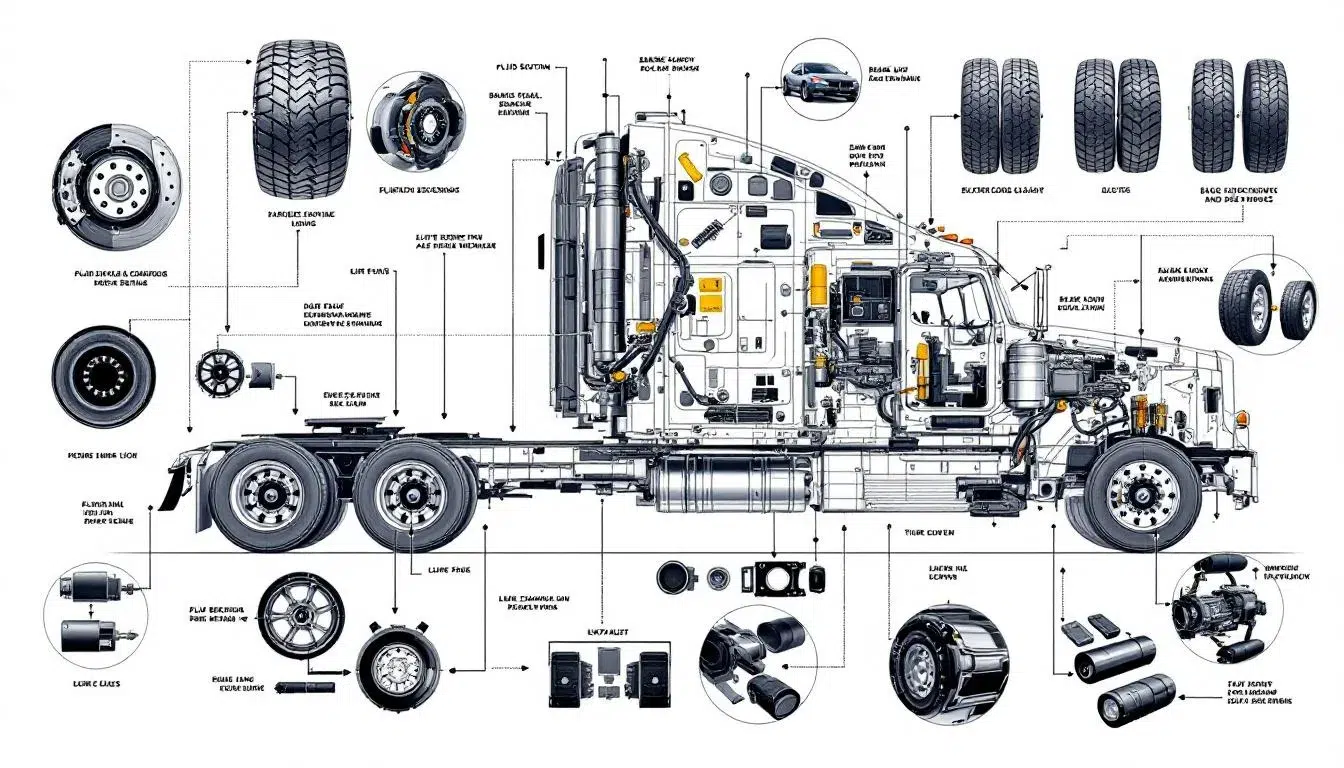

Key Components of a DOT Vehicle Inspection

A DOT Vehicle Inspection involves a thorough check of various critical systems to ensure vehicle safety. The inspection encompasses a comprehensive checklist covering 37 key safety and operational components, including brakes, lights, and steering systems. The type of cargo a vehicle is designed to carry, such as passengers or hazardous materials, can affect inspection requirements and compliance standards.

Frequent issues such as faulty lights, brake failures, and tire defects are often identified during these inspections, highlighting the importance of routine maintenance.

Brake Systems and Tires

Brake system violations, such as worn pads and air leaks, are among the most common failures during DOT inspections. A thorough inspection includes checking for wear and proper function to maintain optimal stopping power.

Similarly, maintaining a minimum tread depth on tires is essential, as low tread depth can lead to inspection failures. A comprehensive pre-trip inspection should always include checking:

- Tire pressure

- Fluid levels

- Lights

- Brakes

to ensure everything is in proper working order.

Lights and Reflectors

Properly functioning lights and reflectors are vital for visibility, especially during low-light conditions. A pre-trip inspection should include checking:

- All lights

- Brakes

- Tires

- The overall condition of the vehicle

Non-functional lights, including burned-out bulbs and missing reflectors, can easily lead to failed inspections.

All lights and reflectors being in working order is a simple yet crucial step for passing a DOT inspection.

Steering and Suspension

Steering and suspension systems must be inspected for responsiveness and integrity to ensure stable vehicle handling. An effective suspension system reduces vehicle body roll and maintains contact between the tires and the road. Properly functioning steering and suspension systems are critical for maintaining vehicle control and safety.

Regular inspection and maintenance enhance vehicle safety and overall performance.

Preparing Your Vehicle for Inspection

Addressing common issues like worn tires, malfunctioning lights, and inadequate brakes, as well as completing all necessary pre-inspection steps, prevents inspection failures and keeps you on the road.

Pre-Trip Inspection Checklist

Performing a thorough pre-trip inspection can help identify potential issues before they become problems during an official inspection. This checklist should include:

- Checking tire pressure

- Checking fluid levels

- Checking lights

- Checking brakes

- Checking the overall condition of the vehicle.

Fixing minor issues during the pre-trip inspection prevents significant problems, saving time and money.

Common Issues to Fix Beforehand

- Air leaks in the braking system

- Worn tires

- Malfunctioning lights

- Inadequate brakes

Addressing these issues ahead of time ensures your vehicle meets safety standards, avoiding re-inspections and fines.

Documentation and Recordkeeping

Accurate documentation ensures compliance with DOT regulations and avoids penalties. Proper recordkeeping maintains compliance and facilitates smoother inspections.

Keeping all necessary documents organized and readily accessible can make the entire inspection process more efficient and less stressful.

For additional information on state-specific documentation requirements, drivers should check with their local DMV or regulatory authority.

Required Documents

A driver’s logbook and certified medical examiner’s certificate (also known as the DOT medical certificate) are key documents for DOT certification. The driver’s logbook tracks hours of service and ensures compliance with federal regulations, while the medical examiner certificate verifies that the driver meets health requirements to operate a commercial motor vehicle and obtain a dot certificate.

Necessary documents for DOT compliance and certification include:

- Roadside inspection reports

- A copy of the driver’s CDL

- Vehicle registration

- Documentation of any medical conditions affecting driving ability, which is critical for DOT certification.

Keeping Records Organized

Organized inspection-related documents allow quick access during DOT inspections. Vehicle maintenance records must be kept organized to facilitate easier access during inspections. Digital records can enhance the efficiency of managing compliance documents and facilitate quicker retrieval.

Maintaining a schedule for regular updates and reviews of DOT-related records ensures ongoing compliance. Digital recordkeeping systems can significantly reduce paperwork clutter and improve the efficiency of accessing and managing DOT documents.

What to Expect During a DOT Vehicle Inspection

DOT inspections focus on maintaining road safety by ensuring compliance with regulations. Understanding what to expect during these inspections can help alleviate some of the stress and ensure that both the person (driver) and the vehicle are well-prepared.

The inspection process typically begins with an initial interaction where the inspector checks the vehicle documents before proceeding to a detailed physical examination physically. The inspection may also include testing or additional tests to assess the driver’s fitness and compliance with health standards.

Initial Steps

Inspectors typically start by greeting the driver and checking their documentation, including licenses and medical certifications. This initial step sets the stage for the rest of the inspection, ensuring that all necessary paperwork is in order before moving on to the physical examination of the vehicle.

Detailed Vehicle Examination

A DOT vehicle inspection includes several key components that ensure the vehicle meets safety standards. During the inspection, the brake systems are scrutinized for functionality, including checking the brake pads, lines, and overall performance. Inspectors assess lights and reflectors for proper operation, which is crucial for vehicle visibility and compliance.

The DOT vehicle inspection process starts with an initial interaction where the inspector checks the vehicle documents before proceeding to the physical inspection. This comprehensive check ensures that all critical systems are functioning correctly, helping to maintain road safety and compliance with federal regulations.

Post-Inspection Procedures

After the inspection, drivers receive a report outlining the results of the inspection. Inspectors inform drivers of any necessary repairs or violations found during the process. Addressing any noted violations promptly is essential for maintaining compliance and safety.

This final step ensures that any issues are resolved quickly, allowing the vehicle to return to service without delay.

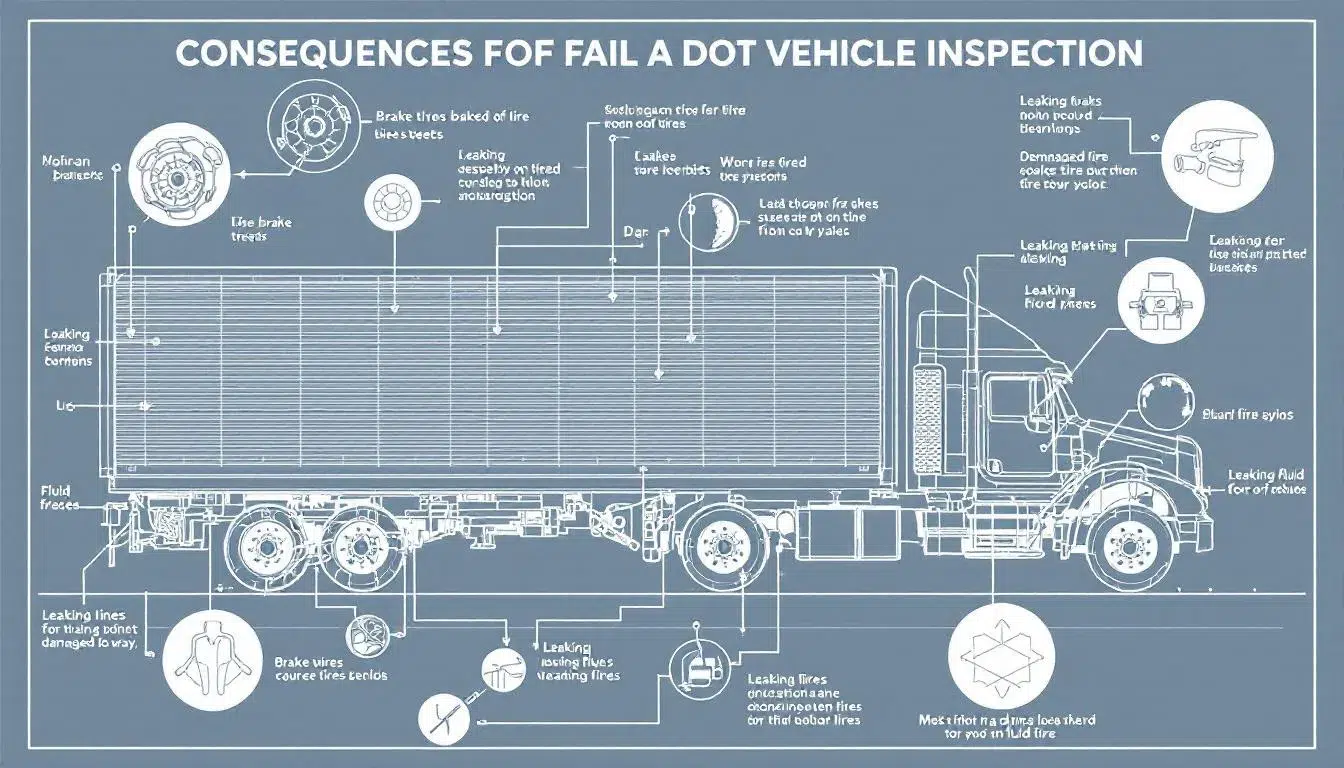

Consequences of Failing a DOT Vehicle Inspection

Failing a DOT inspection can lead to:

- An out-of-service order, preventing operation until issues are resolved.

- A vehicle being placed out of service until necessary repairs are made.

- Monetary penalties for violations, which can vary widely, with some fines potentially reaching thousands of dollars.

Additionally, failing an inspection can adversely affect a carrier’s safety rating, leading to higher insurance costs and a loss of business. Repeated failures can result in higher scrutiny from regulatory agencies and further complications.

Immediate Actions

Drivers should document all findings from the inspection and communicate with their carriers immediately. After addressing the inspection failures, drivers or carriers should seek a re-inspection to validate compliance.

Taking quick and effective action helps ensure that the vehicle can return to service as soon as possible.

Long-Term Implications

Repeated failures of DOT inspections can result in severe consequences such as fines, out-of-service orders, and a negative impact on carrier safety ratings. Consistent failure to pass DOT inspections can damage a company’s reputation, leading to a lack of trust from clients and other stakeholders.

A company facing repeated inspection failures may experience reduced operational capabilities due to lost driving hours, leading to increased costs and inefficiency. Regular maintenance and ongoing training ensure compliance and improve vehicle safety, reducing repeated failures.

Ensuring Compliance and Safety

Regular vehicle maintenance is important for DOT compliance and includes:

- Ensuring the vehicle meets DOT inspection standards.

- Avoiding inspection failures by adhering to DOT standards.

- Keeping vehicle maintenance records up to date for effective compliance.

DOT certification also requires drivers to be physically, mentally, and emotionally fit to operate commercial vehicles safely. The DOT physical exam evaluates a driver’s medical history, blood pressure (including high blood pressure), mental condition, and emotional fitness. Certain conditions, such as sleep apnea or the use of a prosthetic device, may require additional evaluation or documentation to ensure the driver meets safety standards.

Drivers should swiftly correct any issues that caused the inspection failure to avoid prolonged out-of-service status. Critical safety issues identified during the inspection must be addressed before the vehicle can return to service. Repeated failures can damage a carrier’s reputation, making it difficult to secure contracts due to perceived reliability issues.

A history of failed inspections may lead to:

- Increased scrutiny from regulators and potentially legal actions for non-compliance.

- Harm to a company’s reputation and negative impact on future business opportunities.

- Increased insurance premiums.

- Difficulty in retaining clients.

Regular Maintenance Practices

Regular maintenance keeps vehicles in peak operational condition. Regular vehicle maintenance can significantly reduce the risk of mechanical failures during operation. Consistent vehicle maintenance is crucial for reducing operational hazards and improving reliability.

Proactive vehicle maintenance helps pass DOT inspections and ensures the safety of drivers and road users.

Training and Education

Continuous training provides several benefits:

- Keeps drivers and fleet managers updated on the latest DOT regulations and safety standards.

- Reduces the risk of accidents and ensures compliance with federal laws.

- Increases awareness of vehicle inspection processes and compliance criteria among operational staff through regular training sessions.

Effective training can involve workshops, online courses, and refresher courses that cover DOT policies and inspection procedures. Best practices include conducting routine self-inspections and staying informed about changes to DOT regulations through constant education.

Training and education foster a culture of safety and compliance, leading to better performance and lower risk of violations.

Summary

Understanding and passing a DOT Vehicle Inspection is a multifaceted process that involves thorough preparation, regular maintenance, proper documentation, and continuous training. Ensuring compliance with DOT regulations not only enhances road safety but also protects your business from costly fines and reputation damage. By following the guidelines and tips outlined in this guide, you can confidently navigate the inspection process, ensuring your commercial vehicles are always road-ready and compliant. Keep your focus on safety, consistency, and education, and you’ll find that passing a DOT inspection becomes a seamless part of your operations.

Frequently Asked Questions

What is a DOT Vehicle Inspection?

A DOT Vehicle Inspection ensures that commercial motor vehicles meet safety standards and are in good operating condition. This process is essential for promoting safety on the roads.

Who performs DOT inspections?

DOT inspections are primarily performed by state troopers and officials from the Federal Motor Carrier Safety Administration (FMCSA).

What are the common components checked during a DOT inspection?

During a DOT inspection, the key components checked include brake systems, tires, lights, reflectors, steering, and suspension systems. Ensuring these elements are functioning correctly is vital for safety on the road.

What documents are required for a DOT inspection?

For a DOT inspection, you need to have your driver’s logbook, medical examiner’s certificate, commercial driver’s license (CDL), vehicle registration, and any documentation related to medical conditions readily available. Ensuring these documents are in order will help facilitate a smooth inspection process.

What are the consequences of failing a DOT Vehicle Inspection?

Failing a DOT Vehicle Inspection can lead to out-of-service orders, fines, and adverse effects on safety ratings, which may result in increased scrutiny from regulatory agencies. Such outcomes can significantly impact your operational efficiency and reputation.